Home ProductGlobe Valve

PRODUCT RANGE:

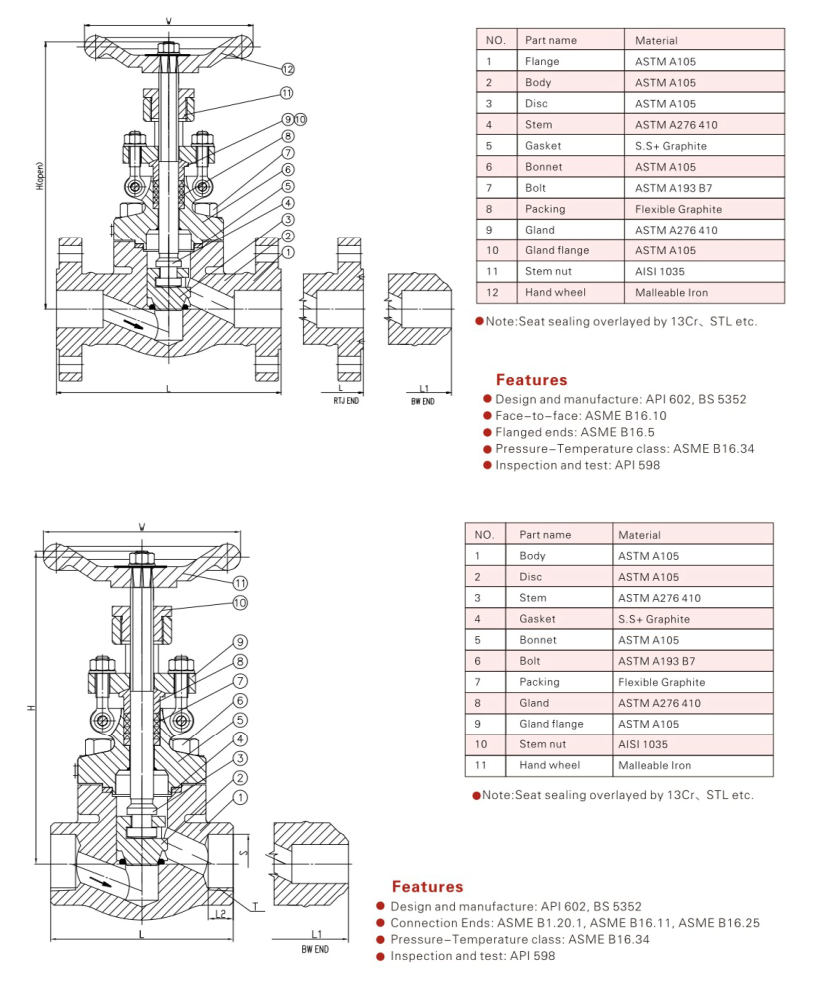

Sizes: NPS 1/2 to NPS2 (DN15 to DN50)

Pressure Range: Class 800, Class 150 to Class 2500

MATERIALS:

Forged (A105, A350 LF2, A182 F5, F11, F22, A182 F304 (L), F316 (L), F347, F321, F51), Alloy 20, Monel, Inconel, Hastelloy

STANDARD

|

Design & manufacture |

API 602,ASME B16.34,BS 5352 |

|

Face-to-face |

MFG’S |

|

End Connection |

- Flange Ends to ASME B16.5 |

|

|

- Socket Weld Ends to ASME B16.11 |

|

|

- Butt Weld Ends to ASME B16.25 |

|

|

- Screwed Ends to ANSI/ASME B1.20.1 |

|

Test & inspection |

API 598 |

|

Fire safe design |

/ |

|

Also available per |

NACE MR-0175, NACE MR-0103, ISO 15848 |

|

Other |

PMI, UT, RT, PT, MT |

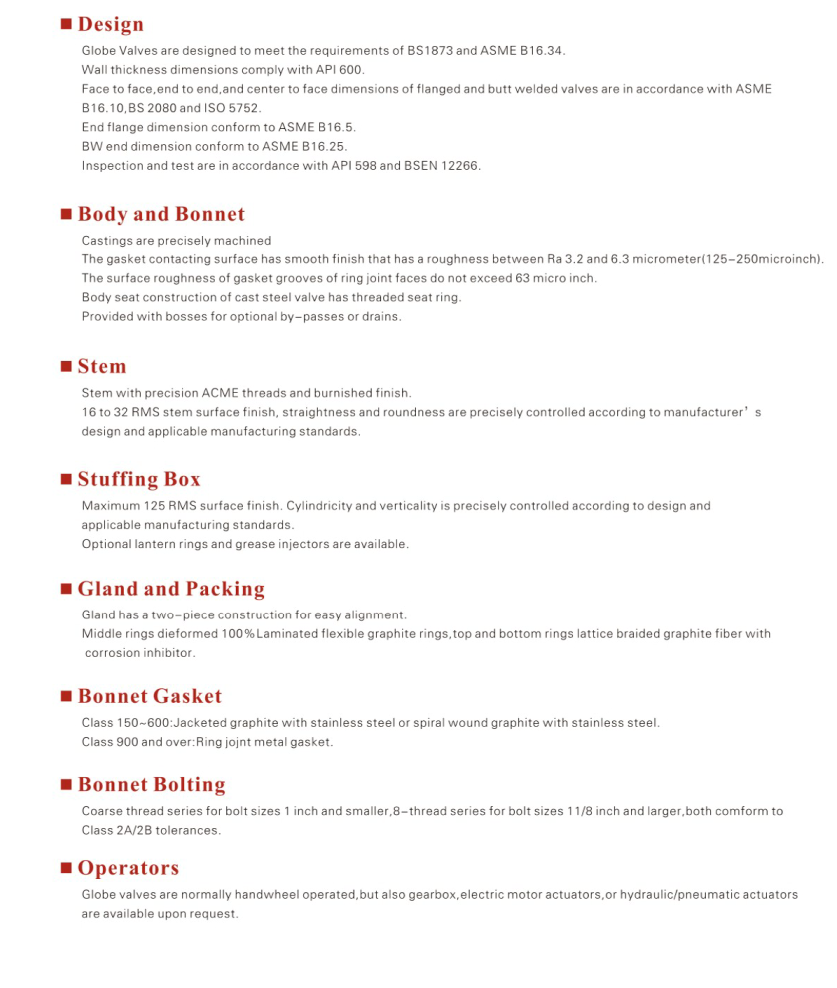

Design Features:

1.Forged Steel,Outside Screw and

Yoke,Rising Stem,

2.Non-Rising Handwheel,Integral Backseat,

3.Reduced Bore or Full Port,

4.Socket Welded,Threaded,Butt Welded,Flanged End

5.SW, NPT, RF or BW

6.Welded Bonnet and Pressure Sealed Bonnet,Bolted Bonnet,

7.Solid Wedge,Renewable Seat Rings,Sprial Wound Gasket,

NSW API 602 globe valve, the opening and closing part of the forged steel gate valve of the bolt bonnet is the gate. The movement direction of the gate is perpendicular to the direction of the fluid. The forged steel gate valve can only be fully opened and closed, and cannot be adjusted and throttled. The gate of the forged steel gate valve has two sealing surfaces. The two sealing surfaces of the most common mode gate valve form a wedge shape, and the wedge angle varies with the valve parameters. The drive modes of forged steel gate valves are: manual, pneumatic, electric, gas-liquid linkage.

The sealing surface of the forged steel gate valve can be sealed only by the medium pressure, that is, the medium pressure is used to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing surface, which is self-sealing. Most gate valves are forced to seal, that is, when the valve is closed, it is necessary to force the gate plate against the valve seat by external force to ensure the sealing of the sealing surface.

The gate of the gate valve moves linearly with the valve stem, which is called the lift rod gate valve (also called the open rod gate valve). There is usually a trapezoidal thread on the lifting rod. The nut moves from the top of the valve and the guide groove on the valve body to change the rotary motion into linear motion, that is, the operating torque into the operating thrust.

Advantages of forged steel gate valve

1. Low fluid resistance.

2. The external force required for opening and closing is small.

3. The flow direction of the medium is not restricted.

4. When fully open, the erosion of the sealing surface by the working medium is smaller than that of the globe valve.

5. The shape is relatively simple and the casting process is good.